A.R.M.O.R

Autonomous Roadway Maintenance Operator Robot

By Team Smooth Operators

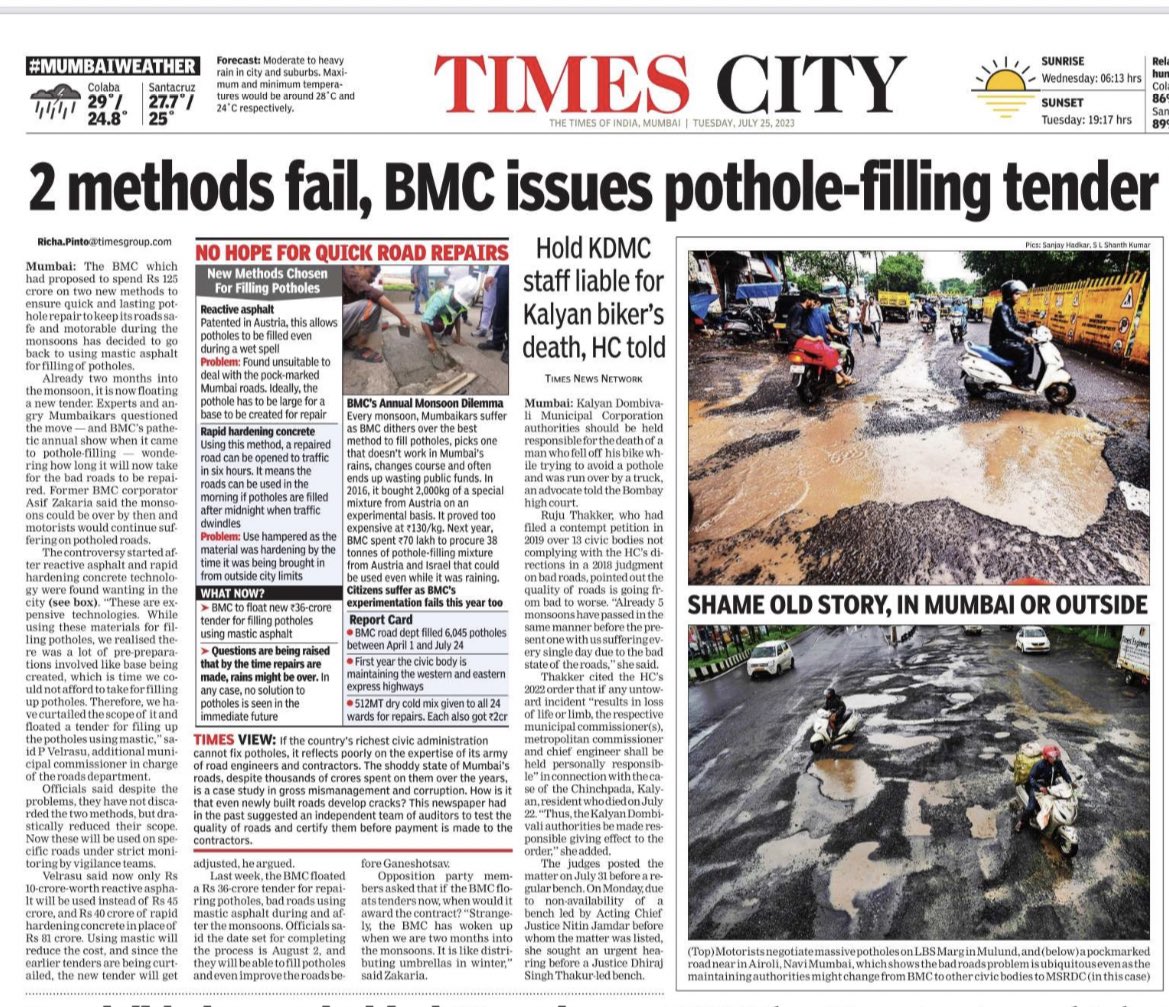

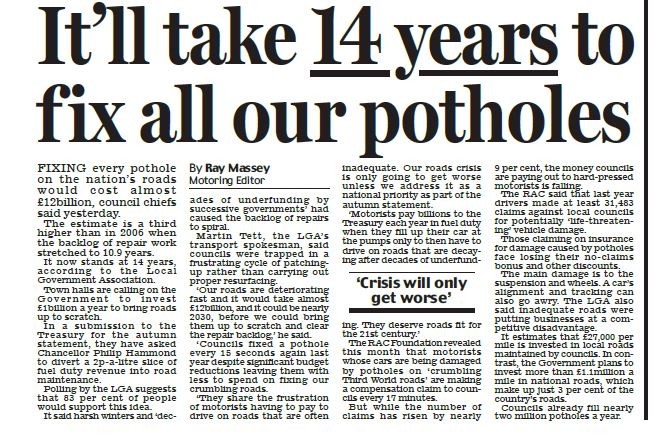

India’s urban roads are constantly plagued by potholes, cracks and surface deterioration, resulting in traffic disruptions, vehicle damage and thousands of accidents every year. Traditional road maintenance methods are slow, labour-intensive and often unsafe for workers. With over 6.6 million kilometers of roads and more than ₹20,000 crore spent annually on repairs, there is an urgent need for a smarter, faster and safer solution.

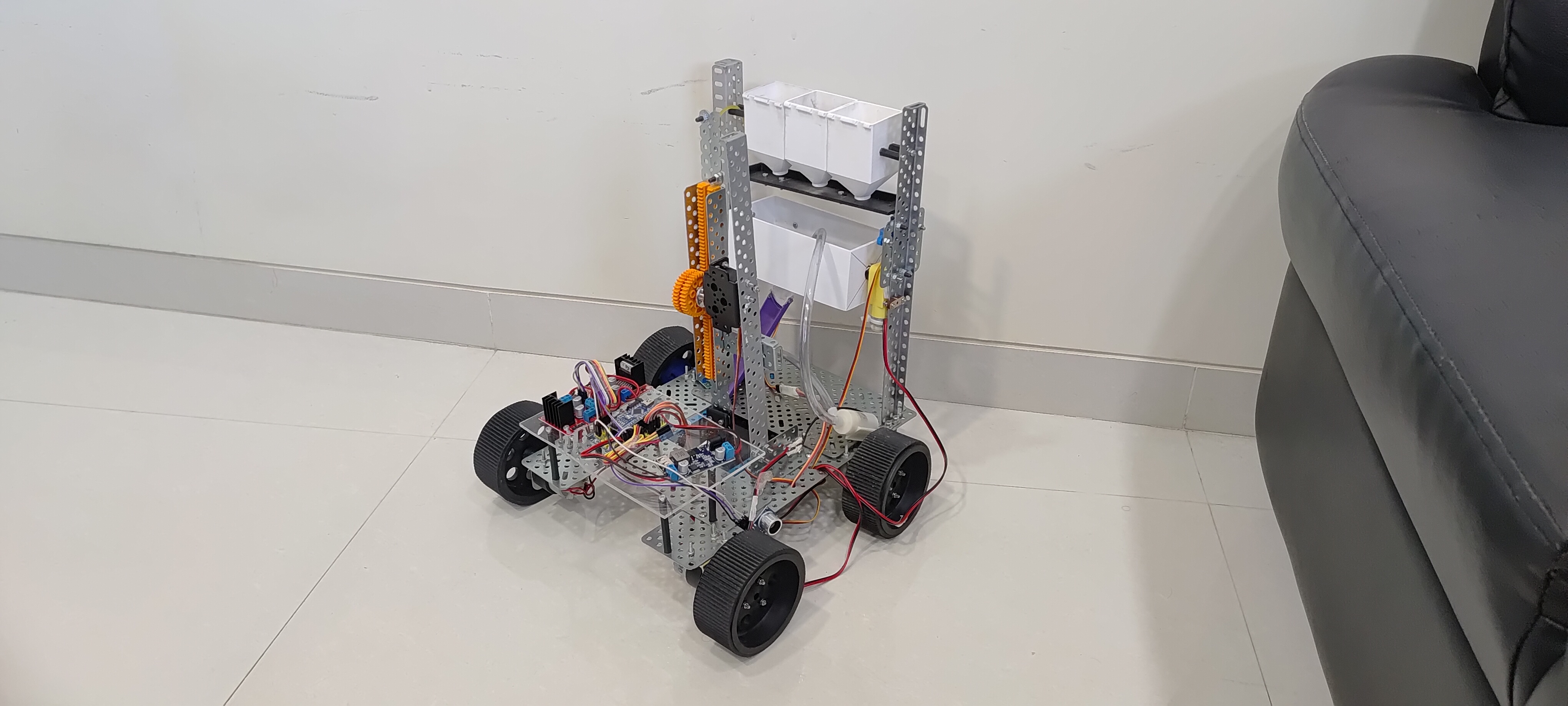

To address this challenge, we present ARMOR – Autonomous Roadway Maintenance Operator Robot. ARMOR is an AI-powered robotic system designed to inspect, detect and repair road damage in real time, with minimal human intervention. It combines advanced sensors, computer vision and autonomous navigation to carry out efficient and precise maintenance, helping cities improve road safety, reduce costs and increase repair durability.

ARMOR represents a step forward in smart infrastructure management and aligns with global goals for safer, more sustainable urban development.

ARMOR is an AI-powered autonomous robot designed to revolutionize road maintenance in India. It addresses the persistent problem of potholes and surface cracks by using advanced robotics,computer vision and machine learning to detect,analyze and repair road damage with minimal human intervention. ARMOR operates independently to inspect roads,identify faults,execute repairs and report data in real time,all while prioritizing safety,efficiency and sustainability.

India’s vast road network (over 6.6 million km) suffers from frequent and dangerous surface deterioration. Traditional repair methods are slow,costly,labor-intensive and pose significant risks to workers. On average,over 2,300 people die annually in India due to pothole-related accidents. In Mumbai alone,over 59,000 potholes remain unaddressed. The system lacks real-time monitoring and proactive maintenance.

ARMOR autonomously detects cracks and potholes, classifies their severity and performs targeted repairs using construction-grade materials. It then applies a temporary Post-Fill Safety Seal to ensure surface stability until permanent resurfacing. The robot also uploads diagnostics to a cloud dashboard for urban planning and enables predictive maintenance to prevent future damage.

Improves road safety by reducing accidents.

Faster and more efficient repairs reduce traffic disruptions.

Reduces costs by up to 40% through preventive maintenance.

Enhances worker safety by minimizing manual involvement.

Increases lifespan of roads through smart interventions.

If implemented widely, ARMOR could save thousands of lives annually, enhance traffic flow, lower civic expenditure and drastically improve the quality of urban infrastructure. It supports key UN Sustainable Development Goals (SDGs) including SDG 9 (Industry, Innovation, Infrastructure) and SDG 11 (Sustainable Cities and Communities).

We are Team Smooth Operators,a group of three robotics enthusiasts from AVM Juhu, Mumbai. Our team includes Ruhan, Aarav and Ayaan and we are excited to participate in the World Robot Olympiad (WRO) 2025.

Ruhan: Responsible for the robot’s design and construction. He works on building a strong and efficient structure to support all the robot’s tasks.

Ayaan: Specializes in integrating the electronics and sensors. He ensures that the robot can detect and respond to its environment accurately.

Aarav: Lead programmer of our team. He focuses on writing and testing the code that brings our robot to life and ensures it functions as intended.

Together,we work as a team,combining our skills in programming,designing and electronics. We are eager to learn,share ideas and create innovative solutions that make a real difference through robotics

India has the second-largest road network in the world, spanning over 6.6 million kilometers. Despite this vast infrastructure,the country lacks an efficient and technology-driven road maintenance system. This results in widespread potholes and cracks that often go unnoticed until they become severe,leading to major safety and financial concerns.

Pothole-related accidents have caused hundreds of deaths across India. The cost isn't just monetary—it’s human.

ARMOR is an AI-powered autonomous robot designed to revolutionize road maintenance in India. It addresses the persistent problem of potholes and surface cracks by using advanced robotics, computer vision and machine learning to detect, analyze and repair road damage with minimal human intervention.

ARMOR operates independently to inspect roads, identify faults, execute repairs and report data in real time, all while prioritizing safety, efficiency, and sustainability.

We were inspired by the increasing number of pothole- related accidents and traffic issues in cities like Mumbai. With over 2,300 annual deaths and ₹20,000 crore spent on repairs,we saw the need for a smarter solution. Our goal was to build a robot that could detect and fix potholes autonomously,improving road safety and reducing manual labor.

The video given below shall give a visual example on how the process works.

The A.R.M.O.R bot combines multiple technologies such as computer vision and AI to deliver seamless pothole detection and repair:

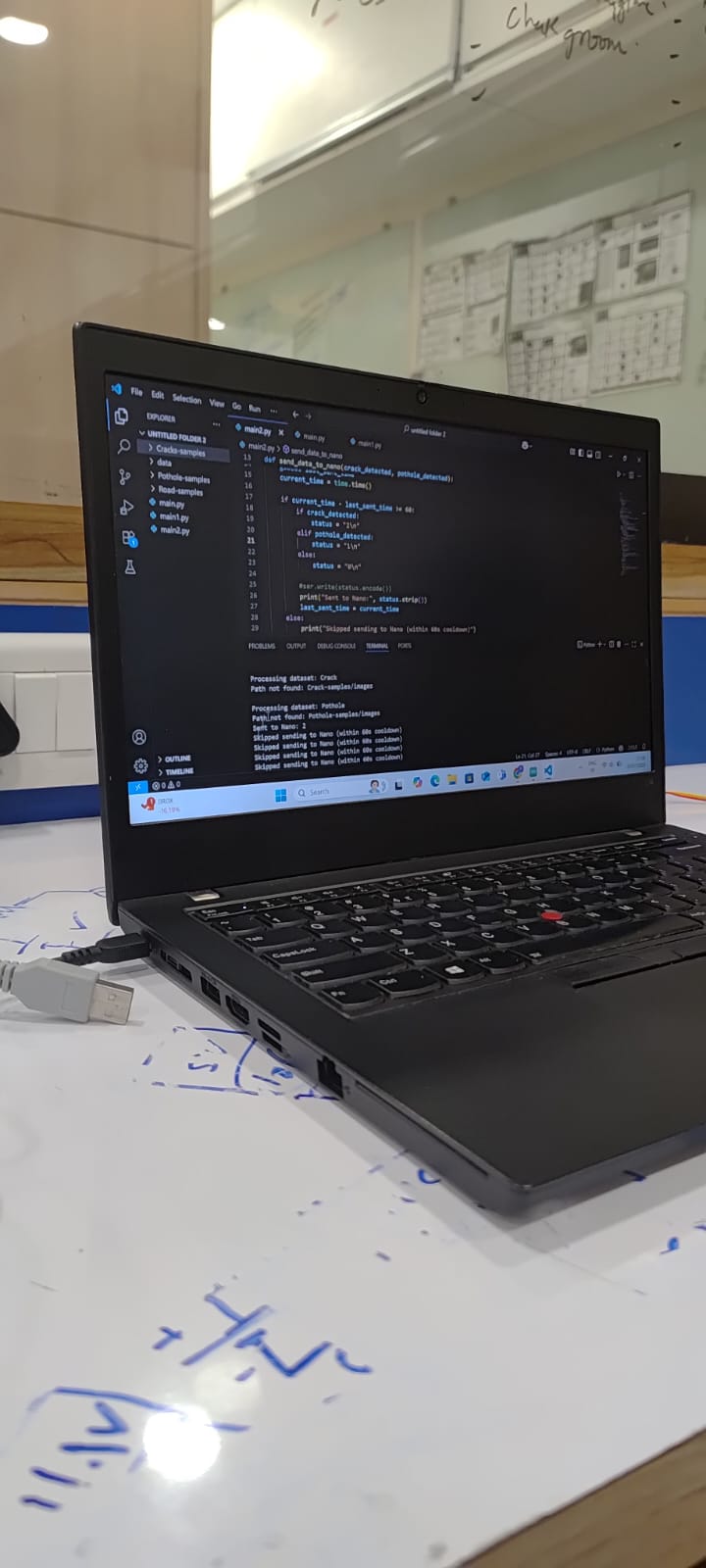

In our project, we used Python and OpenCV to create a basic pothole detection system. The code captures road images using a camera, processes them to identify dark or uneven regions (potential potholes), and highlights them using contour detection. It then assigns GPS coordinates (using a GPS module) and saves this information for repair and logging purposes. This forms the core of our robot’s vision system, allowing it to detect potholes in real-time, assess severity, and trigger the repair mechanism automatically.

Increased Efficiency: By automating repetitive road maintenance tasks, ARMOR frees human resources for complex work and speeds up project completion.

Enhanced Worker Safety: Reduces manual intervention in hazardous environments, decreasing the risk of on-site injuries.

Improved Road Safety: Timely, accurate repairs significantly lower the chances of road accidents caused by potholes and surface cracks.

Cost Reduction: Automation reduces reliance on labor, emergency repair costs and long-term road degradation, optimizing municipal budgets.

Traffic Flow Optimization: Quicker repairs mean fewer roadblocks and less traffic congestion, leading to smoother commutes and economic benefits.

Data-Driven Governance: Real-time data logs from ARMOR support informed decision-making for urban planning and maintenance.